Temperature monitor system for cast resin, dry and oil transformers with 4 inputs for 3 wires PT100 probes.

- Control and showing temperature

- Control of fan systems

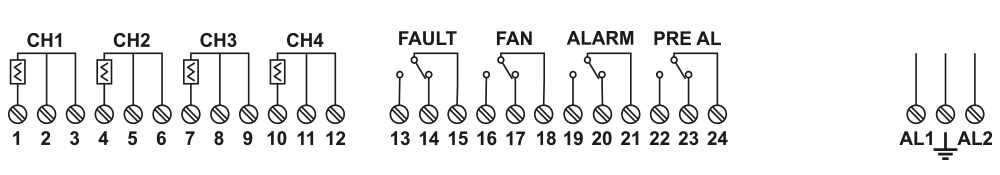

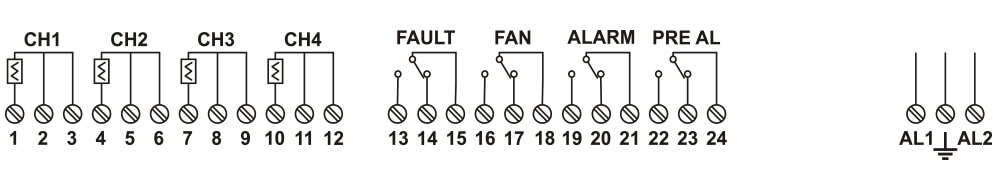

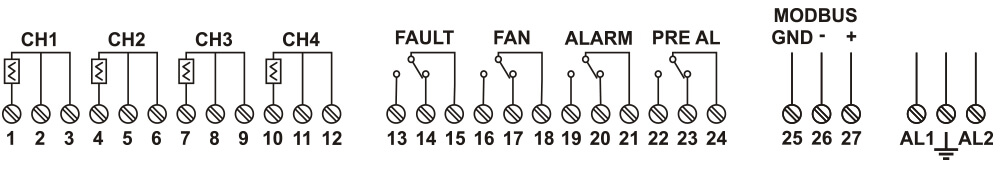

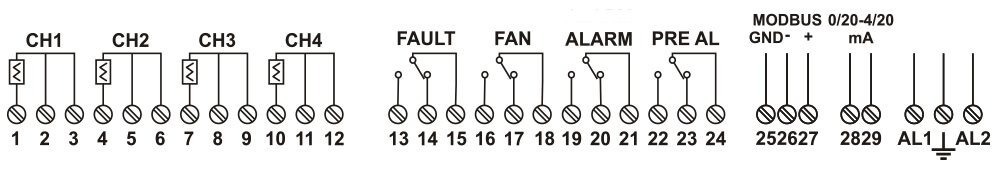

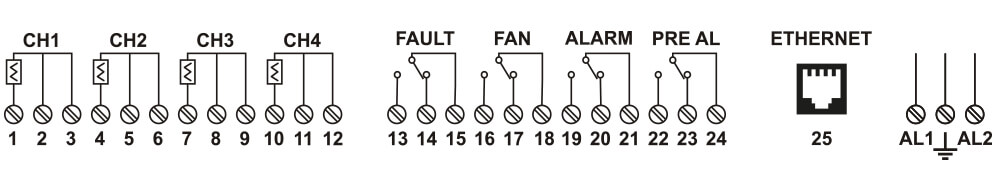

- Four independent PT100 inputs with three wires

- Four 250 Volt 10A AC (resistive load) relays of outputs for the

following functions: pre alarm state, alarm state, fault probe state,

fan control with hysteresis - Manual test relays to simulate or check the reliability of the contact

- Advanced programming menu: is allowed able, enable and set

separately each single channel - Permanent storing of programmed set of pre-alarm and alarm

state, on, off fan and history values achieved - Assembly on panel by simple fixing jaws

- Universal power supply (24 ÷ 240) Volt AC/DC 50/60Hz

- Protocol MODBUS – RTU, RS 485 communication (MT 200 S)

- Protocol MODBUS – RTU, RS 485 communication and galvanically

insulated analogical output 4-20 mA (MT 200 C) - Protocol MODBUS – TCP, ETHERNET communication (MT 200 E)

- Tropicalization (optional)