MT 200W

MT 200W

Temperature controller device, 4 inputs PT100 probes, 4 relays, Wi-Fi communication, MODBUS-TCP protocol

Dimensions

- Box 90x90x115 mm included terminal blocks

- Front panel 96×96 mm

- Weight 0,4 Kg

Power Supply

- Power supply (24 ÷ 240) Volt AC/DC ± 10% 50/60 Hz without polarity respect, absorption 4 VA

Inputs

- Four analogical inputs, temperature control and mapping with PT100 sensor at three wires inside range from -10°C to +200°C

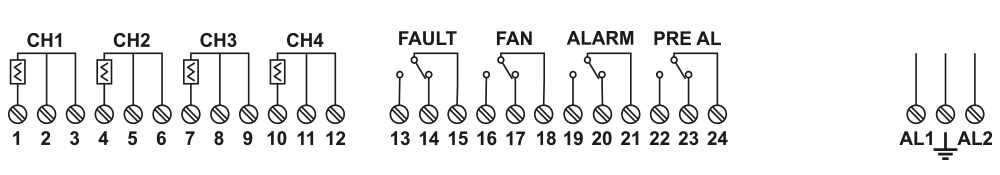

Outputs

- Four relays 250V AC, 10 A max (resistive load), free switch contact

Communication

- Wifi module with secure access according to GDPR protocol with certificates management, serial number and activation key

- Access point always active for the off-line management

- Access by most popular browser (Safari, Firefox, Chrome)

- No program needed, no app to install

- Timestamp events, with RTC clock and buffer battery

- Whip antenna located on the back of the device

- Remote antenna if needed (optional)

- Access point mode for data download in the absence of internet connection and possible import on cloud

Cloud

- Device management for users and groups

- Remote connection to the cloud

- Reading of temperatures, configurations, thresholds, status, and current alarms

- Event storage with datalogger

- RTC always synchronized with Greenwich time

- Possibility of time zone management

- Current temperature graphs and storage

- Data export in CSV

Characteristics

- Self-extinguishable NORYL Box

- Protection degree front panel in polycarbonate: IP65 (IP66 on request)

- Protection degree of rear panel on terminal board side: IP20

- Display with light segments

- Visualisation of max temperature and the relevant channel in the automatic mode

- Alerts of pre-alarm, alarm, probes fault, fanning, manual function, historic highs

- System programming directly by frontal panel

- Possibility to select independently each channel

- Limit of alarm and pre-alarm settable in the range (-9°C ÷ 199°C)

- Precision ± 1% on full-scale ± 1 digit

- Cooling fan control on three or four channels

- Comparison of temperature for cooling fan between two different levels (L and H)

- Four selectable operating modes

- Detection of fault probes, maximum flexibility of managing and simplicity of programming, checking of validity of the insert data during programming phase

- Continuos storage of planned and reached values by each channel (limits and historic highs)

- Dielectric isolation: 2,5 KV AC for 60”

- Software configuration to control the environment temperature

- Resolution 1°C

- Working temperature of device from -20°C to 60°C

- Max allowed dampness in the room 90% not condensing

- Electrical connections with fast-polarised connectors

- Possibility of manual relays switch through menu test relays to simulate and check the reliability of contact

- Technical manual in five languages (and more on request)

- Construction in accordance to EU and RoHS rules

- Tropicalization (optional)